Production lines

- Ergonomically designed working spaces/equipment

- Assembly lines with integrated machine tools

- Packaging lines

- Assembly equipment

- Machining systems (cutting, forming, welding)

- Automation and retrofitting in all production areas

- Various specialized solutions for industry

Slovenia as a country has a worldwide reputation for producing state-of-the-art engineering processes for different industries. To us engineering means designing solutions and production through management of the whole project lifecycle and combining different technologies and processes.

In cooperation with various research groups we perform applicative research in specialized areas. That enables us to manufacture production equipment based on the latest level of development with long-term perspective. With our partners we plan and prepare custom technological solutions through 3 phases.

Phase 1

Planning

We take care of all aspects of preparation and effective execution of the project a working framework, including all activities necessary for the execution of project tasks in perfect synchronization with customer requirements and wishes.

Phase 2

Development & Production

Technical

We define optimal production process and technological needs which are defined in cooperation with specialists from specific areas. We implement the multidisciplinary development with integrated mechanics automation and informatics (mechatronics).

Software

We develop controlling software solution and equipment to connect the modules and control and monitor the production flow.

Phase 3

Assembly

Modular production line solution including mechanical equipment, energetics, tool equipment, work piece flow and other modules is tested and verified. A complete functioning set of components from our own production and other reliable suppliers based on their field of expertise is delivered and assembled on site.

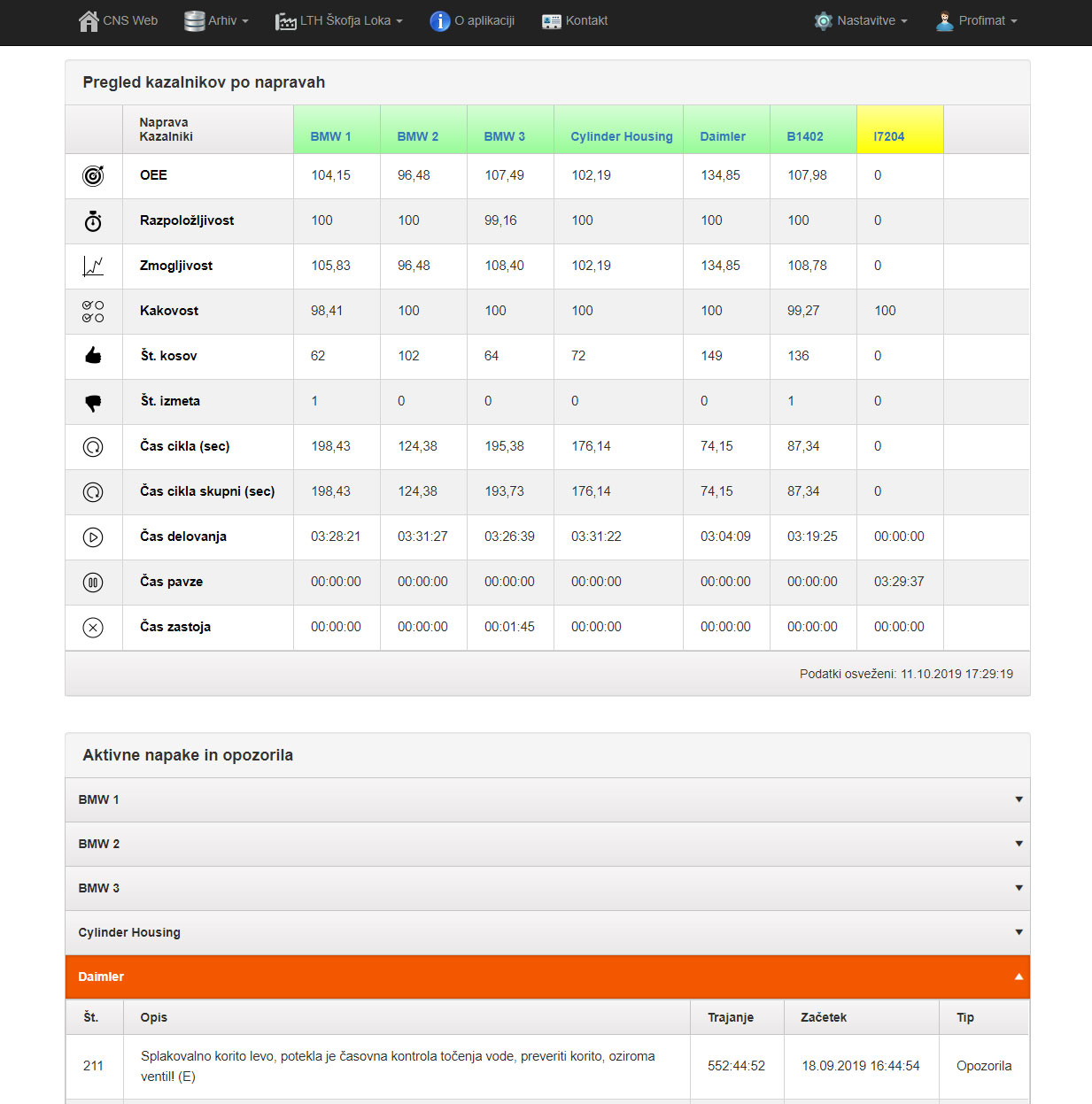

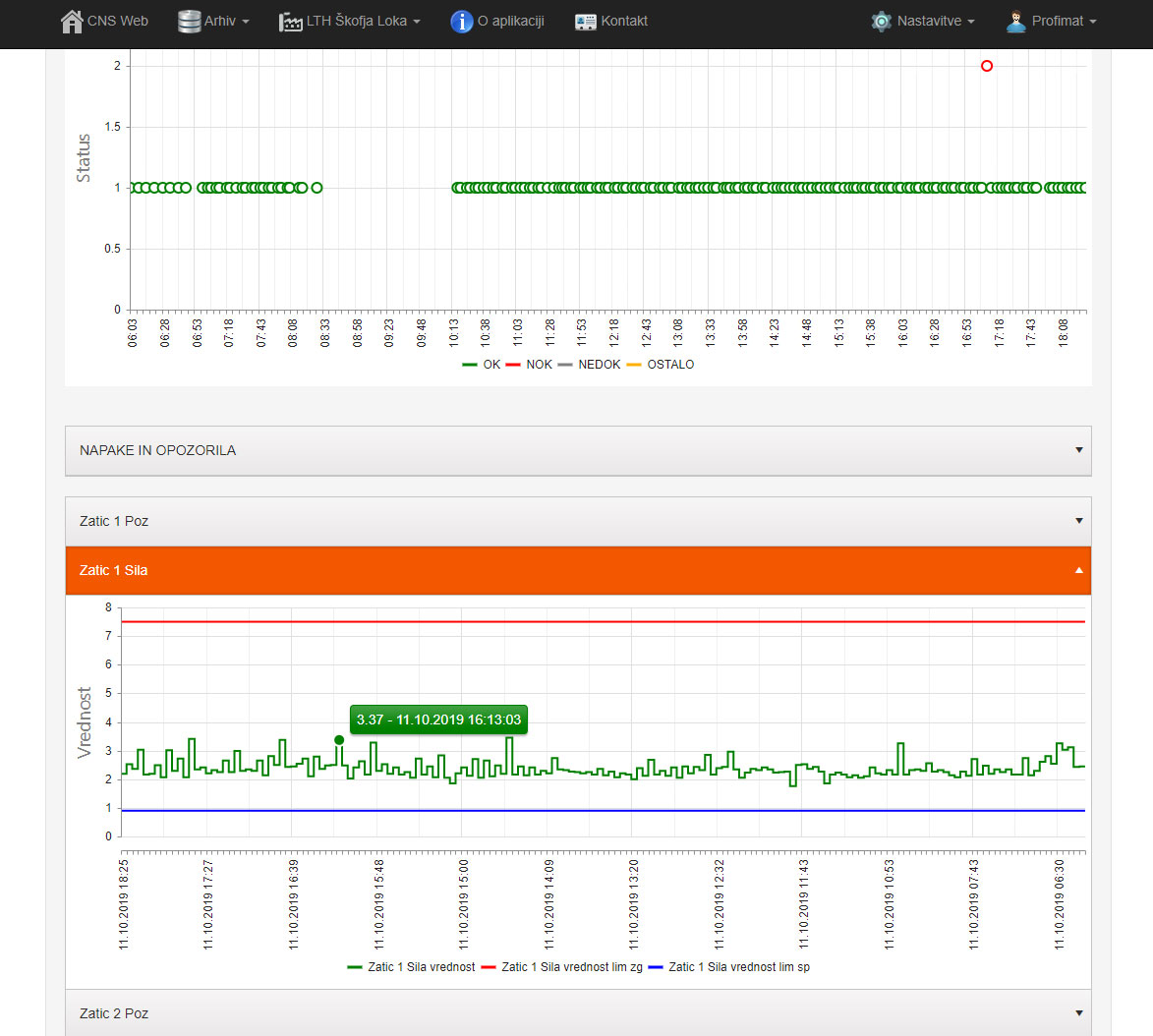

Control & Monitoring Systems (CNS)

CNS is a software tool for real time management and monitoring of production process for Industry 4.0. It’s a complementary tool to existing ERP and MES systems. It automatically collects data from PLC systems and displays it through the user interface that runs locally on production line and is accessible also through PC, tablet or on other mobile devices.

- Monitoring performance indicators

- Status for operation

- Overview current errors with statistics

- Characteristics overview

- Notification system

- Overview archival data

- Can be integrated with other software systems

Smart Production Systems (industry 4.0)

We employ advanced software solutions for real time management and monitoring of production process for Industry 4.0 to complement existing ERP and MES systems. It automatically collects data from PLC systems integrating data flows from numerous sensors installed on the product line to optimize the production flow, alert machine operators of any suboptimal machine (module) performance and minimize downtime through automatic maintenance requests (regular, irregular, preventive).

Key features

- Monitoring performance indicators

- Status for operation

- Overview current errors with statistics

- Characteristics overview

- Notification system

- Overview archival data

- Can be integrated with other software systems

We have refrences in the following industries

Agricultural industry

- Transport systems

- Automations

- Digitalisation

- Machine learning, AI

- Information systems

Household appliances

- Assembly lines

- Automation

- Information systems

- Automation and retrofitting in all production areas

Logistics and Transport

- Manipulators

- Overhead conveyors

- Conveyors (tact, collecting)

Car industry

- Transport systems

- Modernization of assembly lines

- Modernization of sheet metal cutting lines

- Manufacturing systems setup

- Automation

- Video monitoring

Tire production

- Building machines

- Apex lines

- Trimming

- Doubling lines

- Storage during production (sorting)

- Automation

- Informatics – control systems

- Quality control – barcode systems

- Logistics

Rubber industry

- Mixing systems automation

Welding systems

- Steel welding

- AL welding

- Clamping systems

Control systems

- Automation – informatics

- Video monitoring

- MES

- Quality control

Support and Training

Usage / Servicing / Monitoring

In the phase of usage, we offer support by training, counseling, servicing and spare parts to increase the reliability of safe and productive use. We reduce cost and increase reaction time using remote monitoring and online support.

Training

We train machine operators and staff for proper and safe use of our production lines.

Spare Parts / Servicing

A well-organized servicing team of highly skilled and experienced professionals ensures operational reliability and very effective performance of our products and services. A high-level of traceability for use of specific semi-and final products materials is provided.